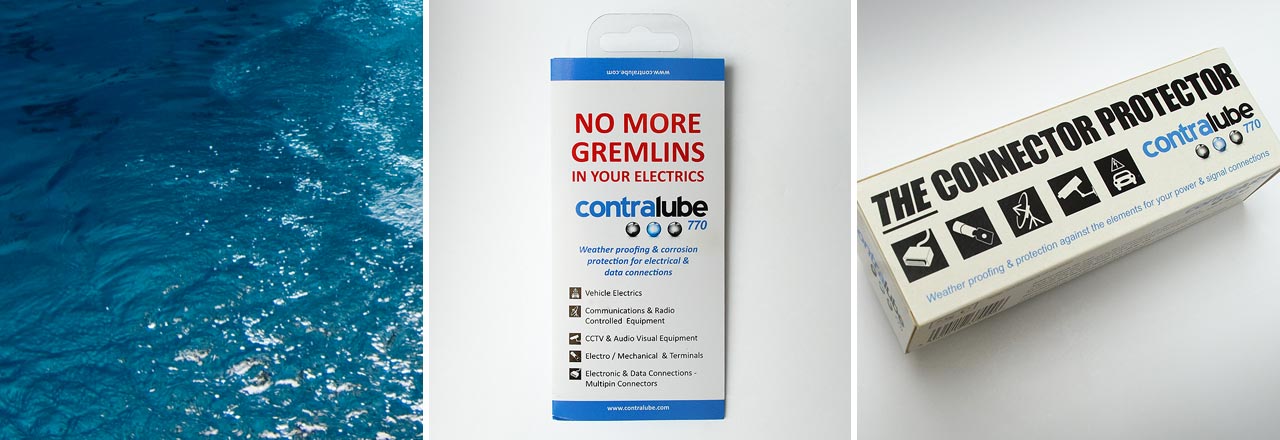

Contralube 770 FAQs

Boatlamps recommend Contralube 770 connector protector gel for lubricating and protecting all lamp holder contacts and all electrical contacts / connections, including navigation lights, battery terminals, CCTV, RF, sockets and so on. Helps prevent lighting and electrical failures die to corroded / oxidised contacts.

How do I use Contralube 770?

Apply generously to the connector or contact surface you wish to protect. In the case of multi pin connectors, squirt directly into the male and female pins/holes of the connector you wish to safeguard. Administer to any spade, bullet or any other type of push fit connector. Contralube is good for any metal to metal contact – for instance an external antenna / RF connection. It can be used to protect CCTV connections and is particularly useful for radio controlled model enthusiasts.

How much Contralube 770 should I Apply?

So long as your contact forces are sufficient (the amount of pressure that is keeping the conductive contact areas together) you cannot over use contralube 770.

How does Contralube 770 work?

Contralube will weather proof / protect your connection and help prevent contact contamination, vibration corrosion and the general build up of oxides. You can load up your electrical and non-electrical connectors and connections safe in the knowledge it will not interfere with the current flow or in the case of non-electrical connection or distort or weaken electronic signal carried through the connection e.g. radio waves or digital signals.

I am applying Contralube 770 to my multi-pin connector, will it cause ‘shorting' faults between the pins?

Contralube can be termed ‘dielectric' which translates to – a material which has negligible electrical or thermal conductivity. Although Contralube 770 may be physically bridging a gap between two separate pins / circuits it will not allow the current to pass between the pins. Contralube 770 has similar conductive properties to air, so if you do not experience arcing / shorting between pins in un-lubricated connectors then the addition of contralube 770 should not change the performance / characteristics of the component. Obviously, circuits utilising extreme currents / voltages are a different matter. We would recommend test/evaluation of contralube 770 before using operationally in all circumstances where extreme currents / voltages are present.

How should Contralube 770 be stored?

Tubes of Contralube 770 should be stored with the screw cap in place and seated correctly. Storage should also be out of direct sunlight and not in extremely hot and cold environments. Please try to keep the tube inside the original carton along with the instruction / support information paper insert.

Contralube 770 seems to turn blue, why is that?

The product contains a UV Tracer additive incorporated into it. Contralube 770 will look clear in appearance although the UV tracer additive means that it will turn a shade of blue when exposed to UV light/sunlight. Sometimes only a small amount of Contralube 770 is used on small connectors. When dispensed in small amounts it is hard to see and the UV Tracer makes the product visible under UV light which assists with quality checks & inspections.

What about the functional life of Contralube 770?

Shelf life is the period following the lubricant’s manufacture during which it is deemed suitable for use without re-testing its physical characteristics. Functional life is determined by durability or accelerated life testing of Contralube 770 in a component under expected operating conditions. Contralube 770 is designed for lifetime component lubrication, which often exceeds 10 years in extreme operating conditions.

What is the shelf life of your Contralube 770?

The shelf life is four years from date of manufacture, provided that the oils and greases are stored in their original, unopened container. The product should be stored away from excessive heat.

How can I clean or remove Contralube 770 from my component?

Start by wiping off all the grease you can reach. Then wipe or brush all surfaces with a solvent cleaner (isopropyl alcohol or similar).

What colour is Contralube 770?

The product is has a clear appearance although the UV tracer additive means that it will turn a shade of blue when exposed to UV light/sunlight

What is UV Tracer?

A UV tracer additive is added so that a presence of the product can be viewed when used in small amounts. The application of a UV light will enable Contralube 770 to be seen – it will show up as blue in colour. With the UV tracer we use the best wavelength for the source of inspection light is 375nm.

What is Copper de-activator?

A copper de-activator is added to inhibit the catalytic effects of metal ions especially copper, so they don’t form a gummy residue (or green slime) on the surface. Since copper is often plating on connectors, and tinned on copper cables, the copper de-activator is used for when the metal plating or tinning is scratched or worn through; this then helps protect any exposed copper from being attacked. Bare copper is exposed every time a tinned cable is cut!

Is Contralube compatible with the materials in my boat?

Compatibility issues are usually related to the base oil of the lubricant. A compatibility table is available which gives a rough guide to the compatibility of Contralube 770 with various plastics and elastomers. As there are numerous types and combinations of plastics this is only a rough guide and a compatibility test is always recommended.

Where can I purchase Contralube 770?

You can buy Contralube 770 direct from Boatlamp’s online store.